Krystal Colloids is a well-known global brand that is trusted for delivering consistently high-quality products that match the precise specifications of our customers. We have spent the last two decades establishing state-of-the-art production facilities, and we currently boast industry-leading client retention rates.

Our products are used in the food and pharmaceutical industries, and as such, we understand the importance of uniform physical and chemical characteristics and the highest microbiological purity. By continuing to invest in innovation, modernization, and operational efficiency in our processing process, we can offer unparalleled quality and customization to our clients worldwide.

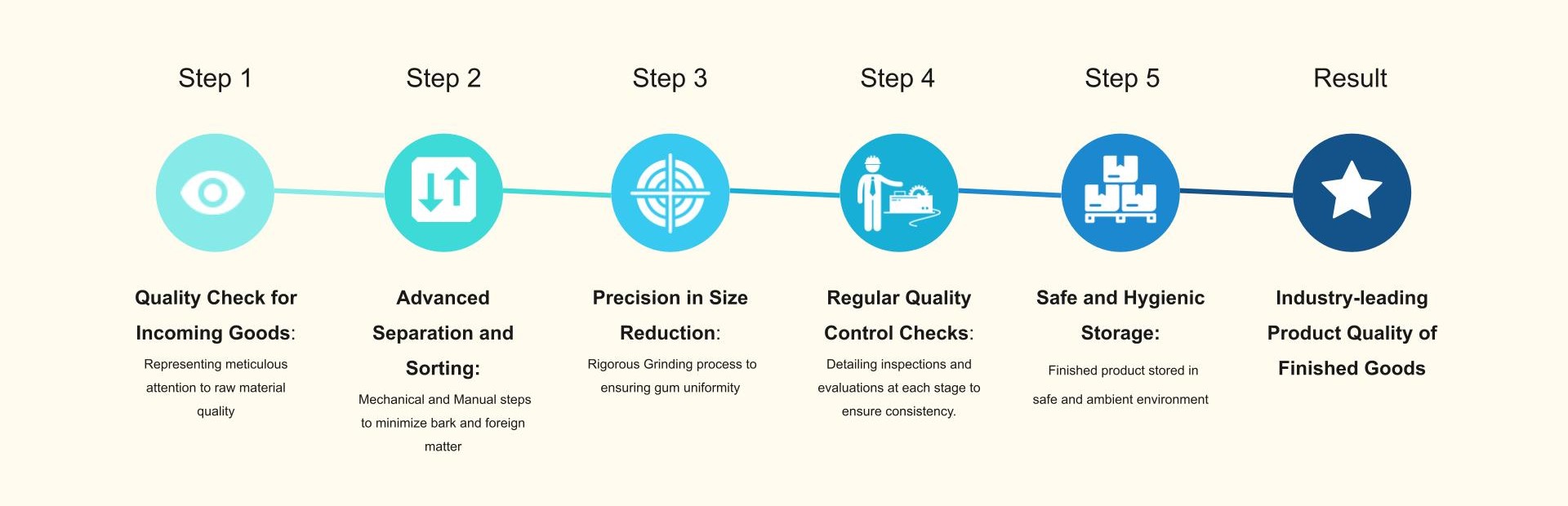

We have implemented rigorous multi-stage quality control procedures, which are regularly and systematically applied at every production stage - from the receipt of raw materials to the finished products.

About our flagship product - Gum Ghatti in which we deal all year round. We are the largest exporter and stockist of different grades of Gum Ghatti, allowing us to cater to our customers promptly. Our unique procurement system and blending, backed by well-thought-out processes, has given us rich dividends. After years of research, we have developed a distinctive method for attaining consistent quality. We neutralize weather effects on raw material by supplying homogeneous finished products through our in-house processes.

Rotational Viscometers: Our lab is equipped with state-of-the-art rotational viscometers, both for low and regular viscosity measurements. This ensures that our products maintain the precise viscosity required for superior quality and performance.

Temperature-Controlled Water Baths: We utilize temperature-controlled water baths to maintain optimal conditions during processing. This careful temperature regulation is essential for preserving product quality throughout the production cycle.

Moisture Meter: Accurate moisture content analysis is key to product quality. Our moisture meter allows us to monitor and maintain the ideal moisture levels precisely, ensuring the longevity and reliability of our products.

Burner for Ash Content Determination: Our specialized equipment for measuring ash content helps us to assess the purity and mineral content of our products accurately, maintaining our commitment to quality and industry compliance.

Precision Weighing Scales: Our array of precision scales ensures exact measurements, which is crucial for consistency and adherence to product specifications.

Ensuring Consistency And Quality At Every Step

Overall, our commitment to quality extends beyond our equipment. Every stage of our production, from the receipt of raw materials to final packaging, is monitored by our Quality Assurance team. We conduct rigorous testing at every processing stage, ensuring that only quality-approved materials are used in our final products.

We uphold the highest standards of hygiene and purity throughout our processing. The pre-packaging fumigation follows stringent industry guidelines, guaranteeing that our products remain uncontaminated and pure.

Rigorous 5-step cleaning and sorting process

At Krystal Colloids, we take pride in our unwavering commitment to quality. Our state-of-the-art processing plant is at the forefront of technological advancement, ensuring that every product we deliver is of the highest standard.

Our processing begins with meticulous attention to the quality of incoming goods, where we uphold stringent standards for raw materials. From there, our innovative processing techniques come into play, each designed to refine and enhance the product while maintaining its integrity.

Quality Check for Incoming Goods: The raw material is validated by our purchasing experts and manually sorted into different grades.

Advanced Separation and Refinement: Our facility employs advanced separation technologies. This ensures the purity of our products and enhances their quality by removing any undesired foreign elements like metals, wooden bark, etc.

Precision in Size Reduction and Sorting: Our processing involves a combination of manual and automated mechanical sorting to reduce the presence of impurities further. This step plays a crucial role in ensuring the uniformity and consistency of our final products.

Regular Quality Control Checks: At every stage of processing, from initial sorting to the final stages, our products undergo rigorous quality control checks. This includes detailed inspections and evaluations to ensure that only the best quality products proceed to the next stage.

Safe and Hygienic Storage: We maintain the highest standards of hygiene and safety in packaging and storage at our processing plant. Our advanced packing and weighing systems ensure that our products are securely and accurately packaged, preserving their quality until they reach our customers.

At Krystal Colloids, our commitment to exemplary customer service is deeply ingrained in every aspect of our operations. Our products, processes, policies, and company culture are meticulously crafted not just to meet but exceed the needs of our clients, ensuring an exceptional service experience. This dedication is a cornerstone of our high client retention rates. Our team is dedicated to serving our clients efficiently and accurately, catering to their specific needs with precision and care.

To propel forward using innovation, our team has established a strong association with national and international governmental and educational organizations. Our customers’ R&D teams can benefit by gaining technical information from an extensive ecosystem of scientists and researchers.